Green Procurement

● Strategy: We emphasize low-carbon and green procurement, integrating low-carbon initiatives and smart technologies to enhance energy and resource efficiency and services.

● Goals of 2030:

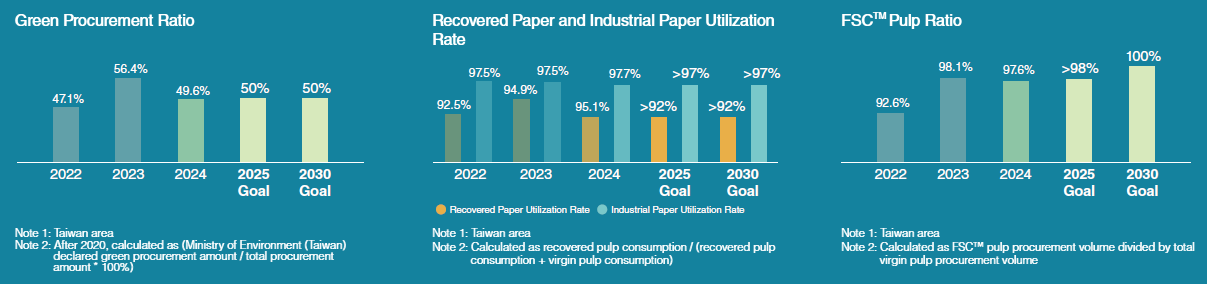

◆ Green procurement prioritizes products and equipment with energy-saving and environmental labels; green procurement ratio reached 50%

◆ All mills/plants receive Green Procurement Excellence Certification from local governments

◆ Recovered paper utilization rate for industrial paper: > 97% in Taiwan; > 94% in Vietnam

◆ Establish an industrial ecosystem to achieve zero waste throughout the recycling value chain

◆ Facilitate recyclers' transformation and diversify recovered materials

◆ 100% FSCTM-certified pulp for sustainable forest management and ecological conservation

Advance Sustainable Procurement to Achieve 50% Green Procurement by 2030

CLC has implemented green procurement to support SDG 12, prioritizing materials, facilities, and office supplies with environmental, energy-saving, and FSC™ certifications to reduce environmental impact and enhance resource efficiency, thereby strengthening supply chain sustainability and resilience.

In recent years, the international community has placed increasing emphasis on the loss of natural capital and promoted the "Nature Positive" approach to reverse biodiversity loss and foster harmony between economic development and sustainability. CLC set a 2030 target for 100% FSC™ pulp procurement in line with SDG 15. In 2024, FSC™ pulp comprised 97.6% of total virgin pulp procurement, a 0.5% YoY decrease caused by global supply constraints and price fluctuations. CLC responded by sourcing local alternative materials to reduce supply risk and maintain environmental commitments.

In 2024, CLC recycled 1,660,000 tonnes of recovered paper in Taiwan, achieving a recovered paper utilization rate of 95.1% for all paper types (+0.2% YoY) and 97.7% for industrial paper (+0.2% YoY). The Vietnam Binh Duong Paper Mill recycled 690,000 tonnes of recovered paper (+16% YoY), with an industrial paper recovered paper utilization rate of 95.1%. Group-wide, CLC recycled 2,350,000 tonnes of recovered paper.

CLC set a long-term goal for green procurement to reach 50% of total procurement by 2030. In 2024, green procurement totaled NTD 8.5 billion, accounting for 49.6% of total procurement (-6.8% YoY). The decline was primarily due to market-driven reductions in virgin pulp procurement. Despite this, CLC remains a leading performer in green procurement, and will continue to advance low-carbon procurement and strengthen the sustainable supply chain.

❙ Conflict Minerals Prohibition

To uphold human rights, CLC avoids the use of conflict minerals sourced from illegal or unethical operations and remains committed to responsible mineral sourcing throughout its supply chain. We prohibit the use of tin, tantalum, tungsten, and gold from the Democratic Republic of the Congo and neighboring regions in the production of industrial paper and corrugated containers. CLC requires suppliers to conduct due diligence on mineral sourcing and address risks of human rights violations and environmental harm. CLC maintains conflict-free sourcing, monitors international mineral management requirements, and communicates with its supply chain.

❙ Prohibited Substances

CLC established the Hazardous Substance Inspection Management Measures to ensure compliance with international regulations. Since 2021, CLC has implemented full material declaration (FMD) management, requiring suppliers to regularly submit hazardous substance verification reports and declarations. All raw materials, finished products, and new materials must comply with prohibited substance controls.

Advancing Recycling Supply Chain Transformation: Cross-sector collaboration to enhance sorting quality, ensure source integrity of recycled materials, and optimize integrated recycling performance

❙ Enhancing Source Separation for Increased Corporate Recycling Efficiency

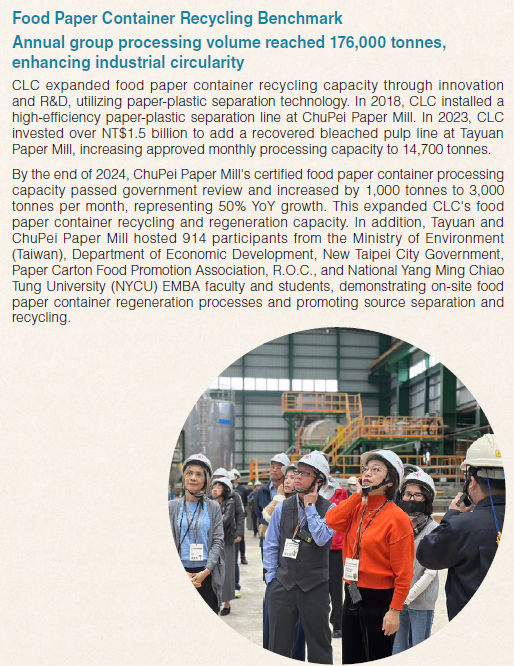

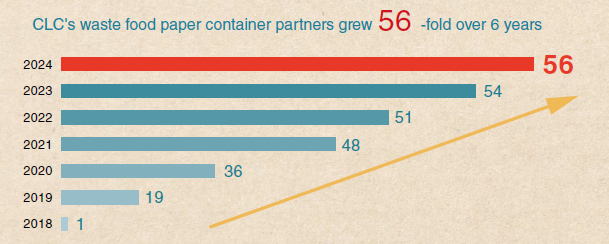

As the largest recovered paper processor in Taiwan, CLC has made circular economy a core strategy. In response to the long-standing issue of 10–13% domestic waste contamination in locally collected recovered paper which compromises recycling efficiency and increases energy consumption during processing, CLC has, since 2018, assisted 167 recycling partners to improve recovered paper quality and meet international standards. In 2024, CLC launched the Food Paper Container 2.0 Project, training key regional partners and supporting 56 suppliers to optimize food paper container sorting and processing, enhancing the local recovered paper supply chain.

❙ Recycling Supply Chain Upgrade: Paper Sludge Reduced by 40%

Since 2018, CLC has set an annual target to support the transformation of at least 2 recovered paper merchants and revised its recovered paper procurement policy. We have also introduced Taiwan's first Recovered Paper Moisture Analyzer and established an e-platform. For 167 recovered paper merchants, CLC implemented a three-stage process—guidance, observation, and replacement—emphasizing source classification and technical support. By 2024, CLC assisted 14 key merchants in transformation, achieving a nearly 40% reduction in paper sludge compared to 2017 through process innovation, and enhanced recycling and energy efficiency.