Product Responsibility and Customer Service

● Strategy: Leverage the recyclability of paper products by integrating green design and green production at all life cycle stages to reduce environmental impact, and ensure customer privacy and product responsibility.

● Goals of 2030:

◆ All products comply with international environmental standards

◆ Expand hazardous substance risk management to overseas operations

◆ Expand digitalization of recurrence prevention to overseas companies

◆ Customer satisfaction score: 90 (Taiwan Parent Company, Consolidated Company)

◆ Maintain strong customer partnerships for mutual growth

◆ Optimize prepress and plate mounting processes to reduce material waste

◆ Promote Waste Reduction Across the Supply Chain

Quality Policy:

"Total Participation, Quality Management, Customer Satisfaction"

Quality is essential to sustainable operations. CLC has implemented the ISO 9001 quality management system at all domestic and overseas plants. Through employee participation and the PDCA cycle, we maintain and improve product quality and customer satisfaction. At the Sustainable Supply Chain Conference, we communicated the company's Quality Policy on hazardous substance management and raw material quality management.

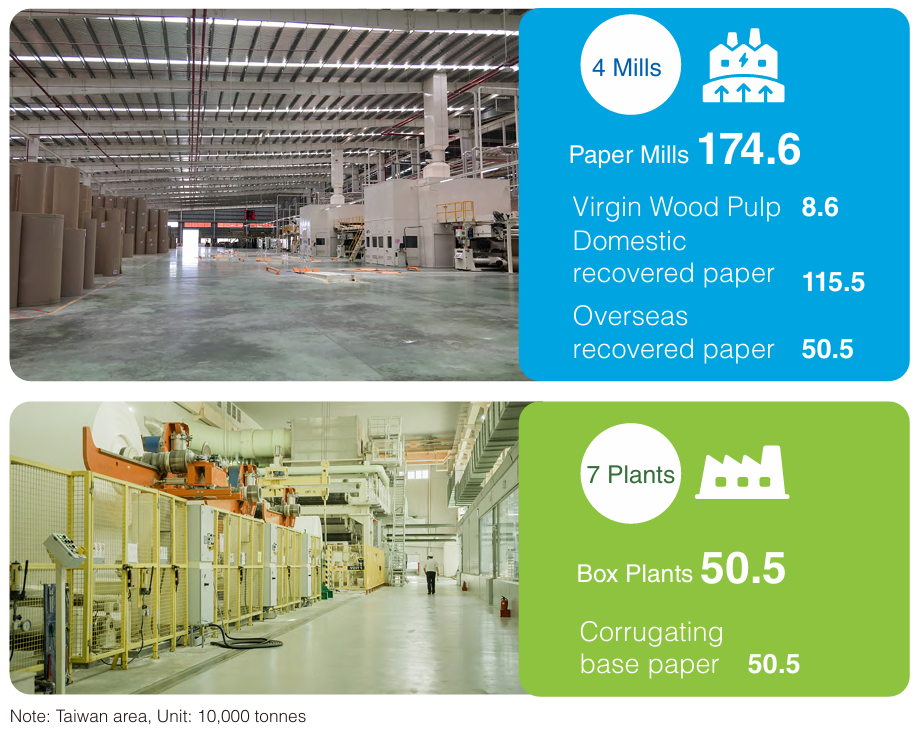

CLC is accelerating product development and upgrading production management, integrating industry partners to recycle used products into the production process for circular reuse and achieving product circularity. CLC operates 4 paper mills and 7 box plants in Taiwan. The paper mills primarily use recovered paper and virgin pulp, while the box plants use base paper from the mills to produce corrugated container products. Materials used are listed in the table below:

In response to sustainability trends, CLC has long used recovered paper as its primary material, reducing carbon emissions and preserving forest resources. The company also actively procures sustainably managed pulp to support forest conservation. In 2024, FSCTM Pulp Ratiofor 97.6% of total virgin pulp procurement in the Taiwan area, achieving other significant results:

.png)

Product Health and Safety

CLC focuses on industrial paper and enforces strict product safety controls. Comprehensive management standards cover raw material procurement, production, and shipment. Dedicated IQC personnel conduct quantitative sampling and adjust frequency based on pass rates. The process is transitioning to supplier management, requiring hazardous substance test reports to replace incoming inspections. If nonconformities are detected, batch-by-batch sampling is implemented to ensure material safety. During production and shipment, production and shipping staff manage quality autonomously, while quality control personnel inspect finished products and warehouse entries and exits at set intervals. Dual control by on-site and quality control staff ensures product compliance and quality.

.jpg)

Industrial Paper Inspection Specifications

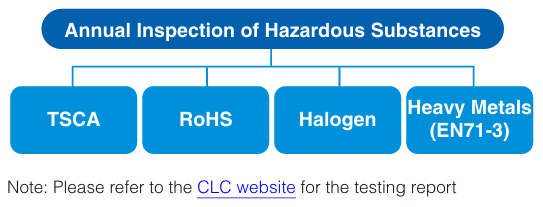

Industrial paper products underwent annual hazardous substance testing by certified inspection agencies, with test items aligned to international standards including EU REACH, SVHC, RoHS, halogen content limits, and EU EN71-3 heavy metal restrictions. In 2024, all product testing results met regulatory requirements. Tayuan Box Plant obtained FSSC 22000 certification, providing higher quality and safe Paper Packaging Solutions.

To address the increase in REACH (SVHC) testing items from 16 to 242 (added 7 items in 2024), the company implemented the Full Material Declaration (FMD) source management system in 2021, replacing finished product inspection reports. This enhanced hazardous substance control and reduced resource waste. Suppliers are required to regularly submit hazardous substance test reports for raw materials to ensure materials are free of hazardous substances before production. In 2024, 28 suppliers submitted reports.

Household Paper Inspection specifications

ChuPei Paper Mill obtained ISO 22000/HACCP food safety management system certification. All products were tested by accredited institutions for total bacterial count, Escherichia coli count, and migration of fluorescent agents as required by customers, with results meeting standards. Eco-friendly toilet tissue and hand towels produced by ChuPei Paper Mill underwent annual bisphenol A (BPA) testing, with zero detected in 2024.

Packaging Design and Certification

To ensure transport safety, packaging structure design incorporates compression resistance and drop tests. All package structure design files are reviewed by SGS to ensure compliance with the Commodity Labeling Act. The FSC™ certification mark is labeled on packaging according to specified position and size requirements for product traceability.

Printing and Plate Making: Waste Reduction and Energy Saving

In recent years, box plant printing plate production has focused on environmental protection and waste reduction. The prepress center has fully implemented digitized drafts to significantly reduce paper and ink consumption, and is optimizing processes such as simplifying registration marks and adjusting plate spacing to further decrease material loss, energy use, and labor costs.

In 2024, certain plants installed film inkjet printers to reduce reliance on traditional chemical developing films, improving production efficiency and environmental performance. The company also held "Water-based Ink Printing Suitability Courses", inviting professional suppliers to share expertise and enhance printing quality.

Driving Plastic Containers Reduction accross the Supply Chain toward Zero Waste

CLC Paper Products Division and the Technology Center collaborated with resin suppliers to implement a recycling and reuse mechanism for 200 kg plastic barrels. Barrels were labeled and sorted by material type, then refilled with the same material for repeated use. This reduced plastic waste and advanced circular resource utilization.

Product and Service Labeling

All household products manufactured and sold by CLC obtained the CNS Mark and passed annual certification by the Bureau of Standards, Metrology and Inspection, meeting CNS requirements for product quality and labeling. Some products provided QR codes for consumers to access SGS test reports. In 2024, no cases of non-compliance with product specifications or labeling occurred.

Paper Studio's children's board games, including Amusement Park Paper Pinball, Animal Adventure Memory Game, and Paper Studio DIY, were certified by the Bureau of Standards, Metrology and Inspection and met toy safety standards.

Customer Privacy Protection

CLC established mechanisms to protect and manage customer data, including enhanced employee training on "customer data" and "information security", and required confidentiality in business operations. In 2024, there were no complaints regarding customer privacy infringement or data loss.

Customer Relationship

CLC implemented a digital customer complaint management system. Quality control and relevant personnel communicate with customers, analyze complaint issues, and identify root causes. Production and responsible units analyze causes and implement preventive actions to avoid recurrence. Digitalization improves complaint handling efficiency and enables digital data management to enhance service quality.

CLC implemented the electronic quality abnormality reporting system at all operational sites in the Taiwan area. The Household Products Division launched the SalesForce CRM platform in 2021 for real-time customer needs tracking and relationship management. The Vietnam paper mill introduced the electronic quality abnormality reporting system at the end of 2022, expanding implementation to other Vietnam sites in 2023. In 2024, the electronic recurrence prevention form for customer complaints was launched. The Paper Products Division, covering Taiwan, Mainland China, and Vietnam, introduced the standardization project in 2022 to strengthen Corrugated Container product quality. All domestic and overseas plants completed the plant standardization project to ensure product quality, production efficiency, and operational safety.

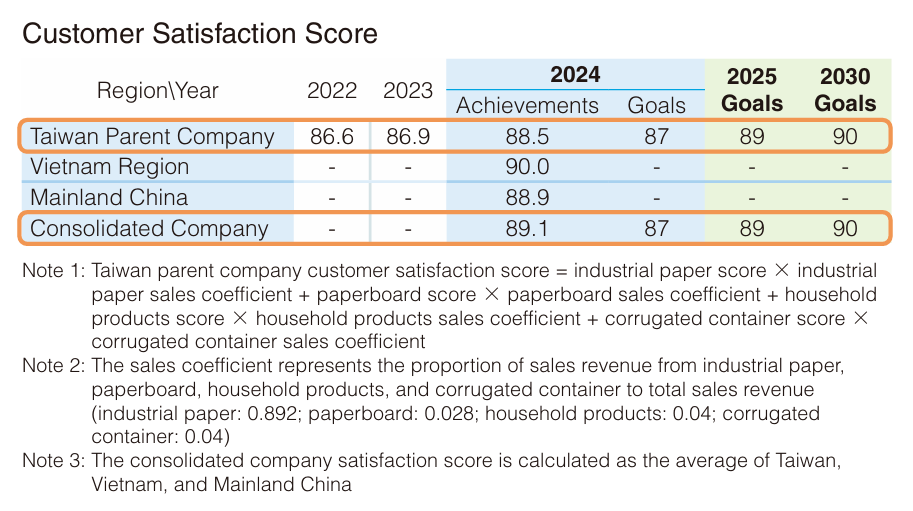

Customer First: CLC Expanded Customer Satisfaction Management and Replicated the Taiwan Model Overseas

CLC established a customer management system and conducts annual customer satisfaction surveys, implementing improvement measures for low-scoring areas. The survey system was extended to overseas sites, including Vietnam. Starting in 2024, customer satisfaction score goals for the consolidated company were set at 89 by 2025 and 90 by 2030 for both the Taiwan parent company and the consolidated company. In 2024, the Taiwan parent company achieved a customer satisfaction score of 88.5 (goal: 87), the Vietnam Region reached 90, Mainland China reached 88.9, and the consolidated company overall reached 89.1 (goal: 87). CLC will continue to enhance customer service, improve production performance, and advance digitalization management to achieve these customer satisfaction goals.

Customer Complaint Management and Digital Optimization

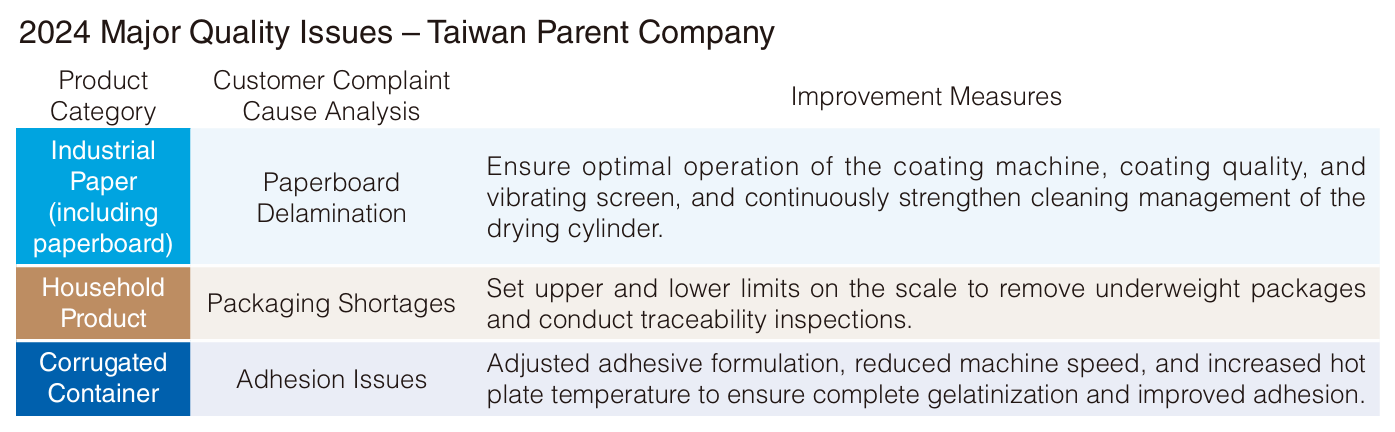

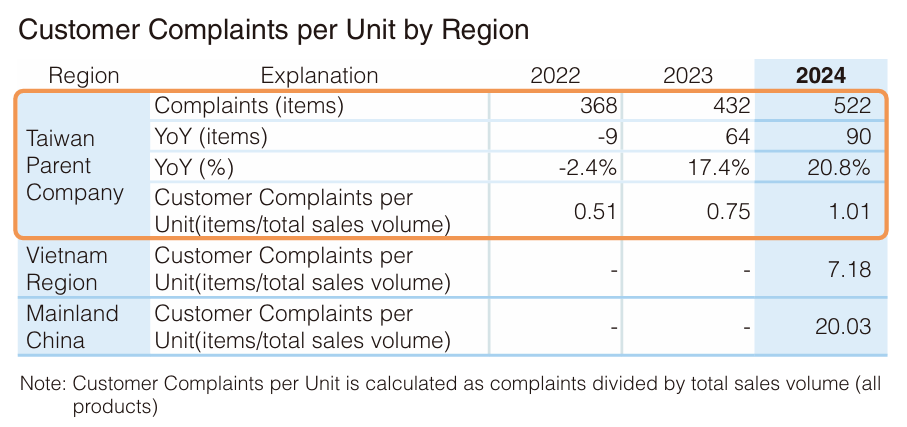

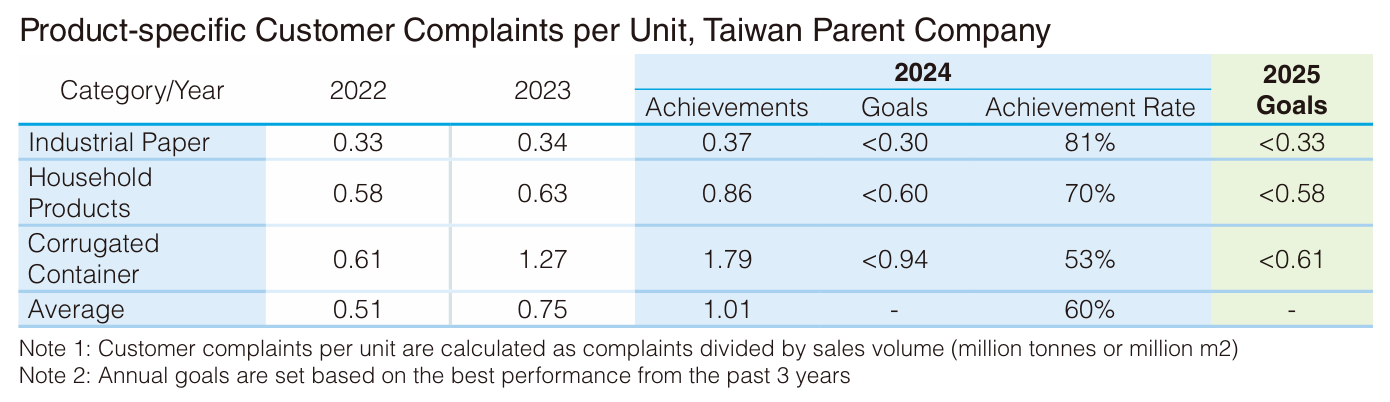

CLC's Taiwan parent company set 2024 complaint management goals by product: industrial paper < 0.30 cases per million tonnes, household products < 0.60 cases per million tonnes, and corrugated container < 0.94 cases per million m2. Achievement rates were 81% for industrial paper (average 0.37 cases), 70% for household products (average 0.86 cases), and 53% for corrugated container (average 1.79 cases), with an overall achievement rate of 60%. In 2024, there were 522 complaints, an increase of 90 from the previous year. The main reasons for increased complaints and unmet targets were paperboard delamination, packaging shortages in household paper, and adhesion issues in corrugated containers. In Vietnam, industrial paper complaints per unit were 0.14 cases per million tonnes, mainly due to base paper creasing; corrugated container complaints per unit were 14.21 cases per million m2, mainly due to warping. In Mainland China, corrugated container complaints per unit were 20.03 cases per million m2, mainly due to poor printing quality.

CLC established a Quality Improvement Team to address items that did not meet goals, ensuring corrective actions and protection of customer rights. The company continues to enhance training and implement digitalization management to improve production and service quality, aiming to minimize complaints and achieve 2025 goals. By 2025, CLC will upgrade the Customer Complaint System at Vietnam and China plants to identify recurring issues and potential risks, supporting quality improvement and product innovation to increase overall customer satisfaction.

The company's products were not prohibited from sale in any market, and there were no incidents involving the sale of questionable or controversial products. All marketing activities complied with national laws and regulations to protect consumer rights and ensure fair competition. The company did not use exaggerated, false, or unfair marketing practices. In 2024, there were no violations of relevant regulations or voluntary standards in product promotion and marketing.