CLC: New Low-Carbon & Green Energy Paper Company

Paper, the daily necessity tied up in our lives, is also an indispensable part of industrial and commercial packaging.

“Cherish Resources and Create a Secondary Forest.” Since the establishment of CLC in 1959, we have made good use of paper's cycle characteristics to reproduce various paper products made out of recovered paper using green paper production. The paper, or industrial paper to be more specific, is the greenest and most sustainable packaging material since it is reused, recycled, and renewed on a continuous basis. Moreover, the paper industry is also a typical and important circular economy industry.

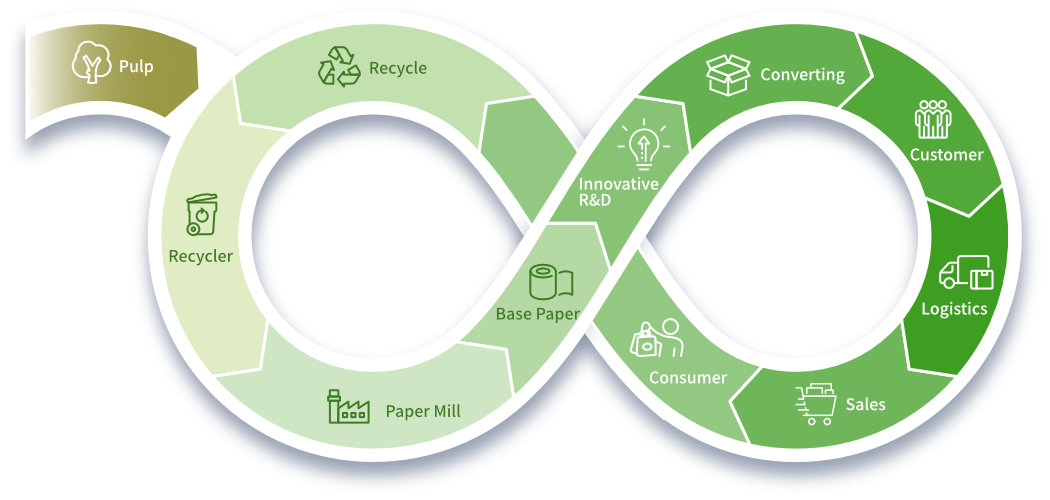

The life circle of CLC's products starts from the use of raw materials and then comes to R&D and design, green production, logistics and distribution, and then the end-consumer. Through the operational mode with papermaking and paper converting as the core, we provide a variety of products and comprehensive solutions for paper packaging to serve clients around the world. Meanwhile, we introduce advanced automatic equipment to improve the production and expand our green low-carbon production sites continuously, so as to strengthen the operational capacity and maintain our leading role in the market. CLC is currently the largest manufacturer of industrial paper products and paper containers as well as one of the largest paper companies in Asia.

To accomplish the vision of zero waste, CLC makes efforts to recycle the process residual material, promote the alternative fuel, and develop green energy via cross-industry cooperation, in order to actively transform ourselves into a new low-carbon green energy paper industry for the 21st century.

Secondary Forest. Circular Economy

For a product life circle which refers to phases of material use, product design, green manufacturing, logistics and distribution, and the end-consumer, we adopt a circular economy model of “renewable resource - paper making - packaging” to research and develop innovative and diverse green products and services, aiming at creating the circular benefits of secondary forests. In recent years, we have been actively integrating the total circulation of three major resources: products, energy, and water through the low-carbon S.M.A.R.T paper strategies: Subtraction-reducing resource consumption use, Materials-turning waste to energy, AI-smart production-sales, Recycling-reusing recovered paper, and Technologies-advanced processes to transform traditional factories into eco-friendlier smart and recycling plants.

As a leading paper manufacturer, CLC is committed to developing a circular economy sustainable business model focused on environmentally friendly products and services. CLC continues to enhance processes, adopt advanced environmental equipment, and implement intelligent production and sales systems to increase the use of recovered paper, improve product quality, and achieve carbon reduction. In 2024, CLC's Taiwan Parent Company utilized 1.66 million tonnes of recovered paper (+1.9% YoY, 32,000 tonnes). The recovered paper utilization rate rose by 0.2% to 95.1%. For industrial paper, the utilization rate also increased by 0.2% to 97.7%. All paper types and industrial paper met established goals. In 2024, Vietnam Binh Duong Paper Mill utilized 690,000 tonnes of recovered paper (+16% YoY, 100,000 tonnes), raising the recovered paper utilization rate for industrial paper to 95.1%. Groupwide, CLC utilized 2.35 million tonnes of recovered paper in 2024, generating resource circulation benefits and indirectly preserving 47 million trees, contributing to secondary forest creation.

Note 1: The number is calculated based on the Muzha incinerator’s 196,728 tons of refuse disposal in 2019.

Note 2: Using each tone of recovered paper may save 20 trees from felling and reduce 5.8 tons of carbon emission.

Note 3: Assuming that there are 6,000 trees in a Daan Park.

Green Production.Save Energy and Reduce Carbon Emission

CLC implemented the ISO 50001 energy management system across all mills/plants, established energy management mechanisms, and regularly reviewed energy efficiency and energy-saving targets. To meet the annual 1% energy-saving commitment, each mill/plant developed specific energy-saving plans, including high-efficiency cogeneration systems, renewable energy installations, and equipment optimization. Smart systems were introduced to enhance carbon reduction performance and support the transition to a new low-carbon & green energy paper company.

.jpg)

Innovative Circular Economy

First Paper Maker Completely Recycling Food Paper Containers

Implement the Total Circular Resource to Respond to the Plastic-Reduction Policy

Annual food delivery and takeout in Taiwan generated over 8 billion waste food paper containers. The Ministry of Environment (Taiwan) designated food paper containers as mandatory recycling items, requiring processing plants to separate plastic lining from paper pulp for recycling and reuse. Due to limited public awareness, many consumers disposed of these containers as general waste or mixed them with regular waste paper, resulting in low recovery rate and increased processing costs for paper mills.

CLC Leads Global Waste Food Paper Container Processing Volume

Since 2018, CLC established the 1st food paper containers total recycling line at the ChuPei Paper Mill. In the same year, CLC launched the Recycling Supply Chain Transformation and Upgrade project, supporting 167 recycled paper suppliers in upgrading operations, achieving source separation, and reducing recovered paper residual waste by nearly 40% compared to 2017. CLC also established a dedicated recycling system for paper lunch boxes. By 2025, the number of waste food paper container recyclers reached 56, a 56-fold increase from 2018. Separated impurities and plastic lining are converted into green energy fuel and eco building materials, supporting a sustainable business model.

CLC advanced waste food Paper container recovery by installing a 66,000 tonnes recovered bleached pulp line at Tayuan Paper Mill in 2023. By the end of 2024, ChuPei Paper Mill's certified processing volume for food paper containers was approved by the government, increasing by 50% to 3,000 tonnes per month. The group's total certified annual processing volume for waste food paper containers reached 176,000 tonnes, enabling the recovery of over 50% of Taiwan's waste food paper container resources and achieving a carbon reduction of 1.02 million tonnes. CLC engaged associations, schools, government agencies, and enterprises through diverse collaborations to expand carbon reduction impact and opened its factories for public visits to raise awareness of sustainability responsibilities.

CLC's Document Destruction Technologies Enabled Recycling, Accumulating a Cumulative Carbon Reduction of 82,250 tCO2e and Preserving 284,000 Trees

Since 2013, CLC has utilized existing pulp dispersion equipment to provide free confidential document destruction services. Over 12 years, CLC assisted nearly 400 partners—including government agencies, listed companies, financial and insurance firms, and defense units—by converting 14,181 tonnes of confidential documents into over 61.26 million packs of eco toilet tissue, demonstrating both environmental and economic benefits..

.png)

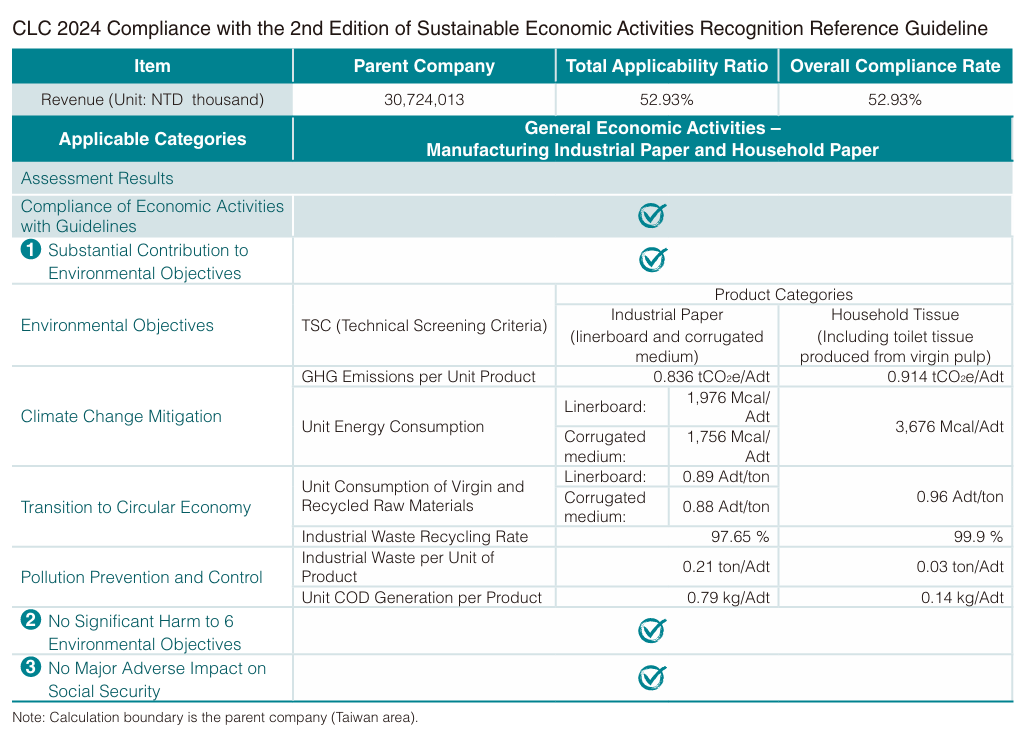

Sustainable Economic Activities

According to the Taiwan Sustainable Economic Activities Recognition Reference Guideline (2nd Edition), CLC produced paper and paperboard through a circular economy model, meeting the criteria under the General Economic Activities category. In 2024, CLC reported revenue of NTD 30.72 billion in Taiwan, with 52.93% both applicable to and compliant with sustainable economic activities. This covered the production of low-carbon industrial paper (linerboard and corrugated medium) and household paper (including toilet tissue made from virgin pulp). All activities met 3criteria: substantial contribution to at least one environmental objective, no significant harm to any of the 6 environmental objectives—climate change mitigation, climate change adaptation, sustainable use and protection of water and marine resources, transition to circular economy, pollution prevention and control, and protection and restoration of biodiversity—and no significant harm to social safeguards.