Waste to Resource

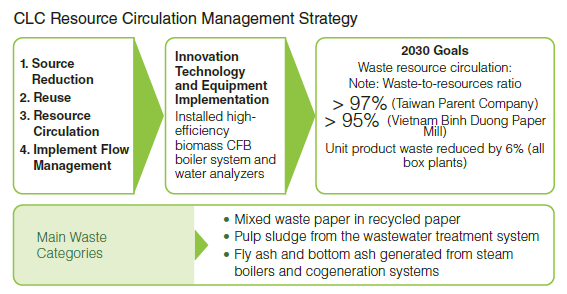

● Strategy: Promote circular reuse of resources, expand waste resource utilization channels, and increase the resource utilization rate annually to achieve the vision of zero waste.

● Goals of 2030:

◆ Waste-to-resource ratio:> 97% (Taiwan Parent Company);> 95% (Vietnam Binh Duong Paper Mill)

◆ All box plants to reduce unit product waste by 6% (base year: 2024)

◆ Advancing Circular Economy in Waste Management

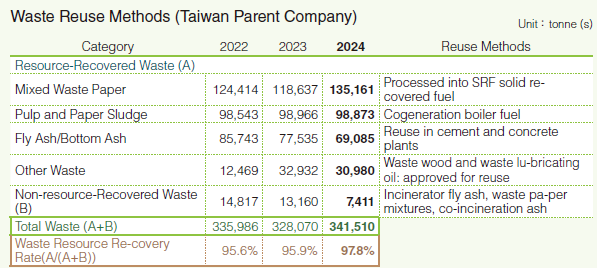

2024 Waste-to-resources Ratio Reached 97.8%, Exceeding Annual Goals

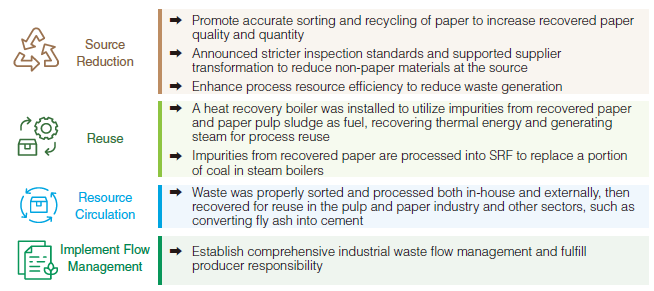

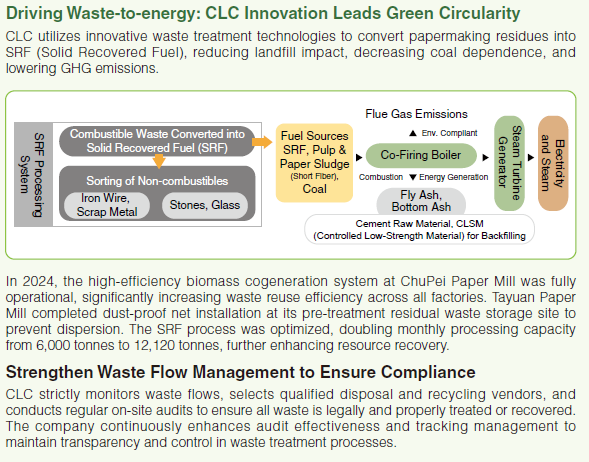

CLC adheres to the principle of "no waste, only misplaced resources" and is committed to sustainable resource management. The company implements four core strategies—source reduction, reuse, resource circulation, and flow management—to enhance waste treatment efficiency. All waste generated is classified as general industrial waste, with no hazardous industrial waste produced. Operations comply with environmental regulations and ensure environmental safety.

CLC advanced circular economy by converting process residues into resources and expanding the reuse of waste paper mixtures and co-combustion ash. In 2024, waste reuse reached 334,099 tonnes, raising the waste-to-resources ratio to 97.8%, up 1.9% from last year and surpassing the 97% annual goal. Vietnam Binh Duong Paper Mill achieved a 98.7% waste-to-resources ratio and set a medium- and long-term goal of 95%.

To enhance resource efficiency and waste management, CLC set a 2030 target for all box plants to reduce unit product waste by 6%, using 24 kg/m2 in 2024 as the baseline. This target aligns with circular economy principles and serves as a quantitative benchmark for internal risk control and recycling performance, strengthening consistent sustainable management across all sites.